UvA researchers report first MAX phase catalysis

27 November 2017

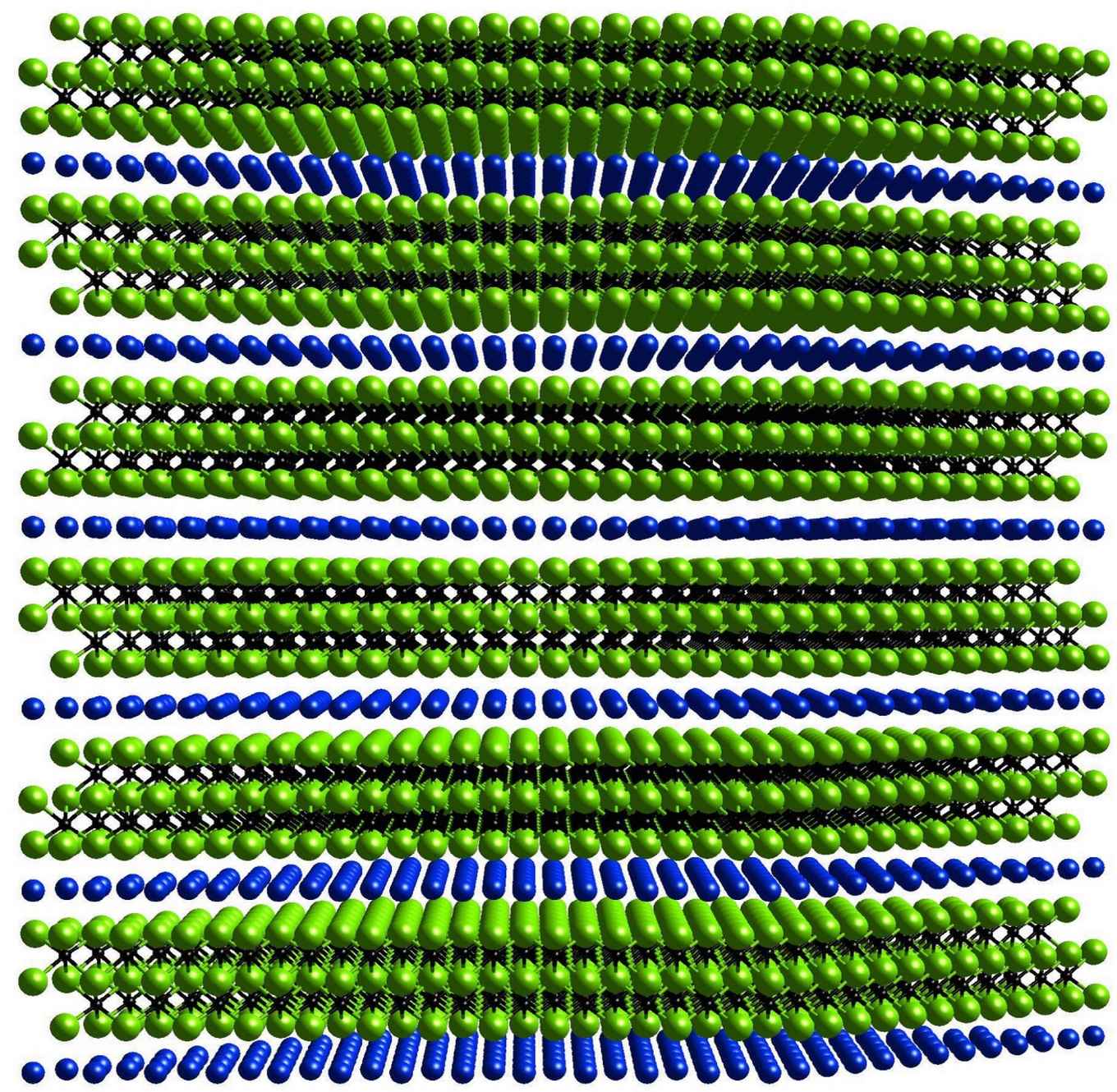

MAX phases are a family of ternary carbides and nitrides with layered hexagonal crystal structures possessing an unusual combination of chemical, physical, electrical, and mechanical properties. Dr Shiju Raveendran, Prof. Gadi Rothenberg, Dr Edwin Gnanakumar and MSc student Wesley Ng from HIMS now report the first application of such a MAX phase in heterogeneous catalysis. They show that despite the absence of a formal oxide lattice, the titanium-aluminum carbide Ti3AlC2 efficiently catalyses the oxidative dehydrogenation of n-butane to butenes and butadiene. The work was conducted in collaboration with Drexel University (US) Tata Steel (The Netherlands), the University of St Andrews (UK), Missouri State University (US) and the Bhabha Atomic Research Centre (BARC, India).

MAX phases: neither oxides nor pure metals

MAX phases exhibit a unique combination of ceramic and metallic properties. They conduct heat and electricity like metals, yet they are elastically stiff, strong, brittle, and some are heat-tolerant like ceramics. Phase-pure bulk samples of the MAX phase were first synthesized by Prof. Michel Barsoum of Drexel University. The combination of metallic and ceramic properties and high stability as well as the fact that they differ from most 'conventional' catalytic materials (they are neither oxides nor pure metals) triggered the curiosity of the HIMS research team.

The team tested Ti3AlC2, one of the MAX phases, as a catalyst for the oxidative dehydrogenation of n-butane to butenes and butadiene. These are important intermediates for the synthesis of polymers and other compounds. Traditionally they are obtained from steam cracking and catalytic cracking units, but oxidative dehydrogenation is gaining more importance as it enables the production of alkenes directly from natural gas and shale gas. Indeed, the research showed that the MAX phase efficiently catalysed this reaction. It was stable for at least 30 h on stream, even at low O2:butane ratios without suffering from coking.

Probing MAX phase catalytic secrets

Since the MAX phase has neither lattice oxygens nor noble metals, the team further probed the secret of its catalytic activity. Electron microscopy studies in St. Andrews and Positron Annihilation Lifetime Spectroscopic studies at BARC showed numerous defects, which can act as adsorption as well as reaction sites. XPS and N2O chemisorption studies by Tata Steel proved the formation of a surface mixed oxide with several oxygen vacancies. DFT studies of model Al-Ti-O surfaces in Missouri State University confirmed that oxidative dehydrogenation of butane is energetically favourable on such a mixed oxide surface. Thus, the unique catalysis by this carbide phase can be ascribed to its defective structure and non-stoichiometric oxide layer on the surface.

Article

Ng, W., Gnanakumar, E., Rothenberg, G., Batyrev, E., Sharma, S., Pujari, P., Greer, H., Zhou, W., Sakidja, R., Barsoum, M. and Shiju, N. R., Ti3AlC2 MAX-phase as an efficient catalyst for oxidative dehydrogenation of n-butane. Angew. Chem. Int. Ed., 2017. DOI: 10.1002/anie.201702196