UvA researchers invent novel catalyst to convert carbon dioxide

New catalyst provides a possible means to sustainably utilise CO2

6 April 2017

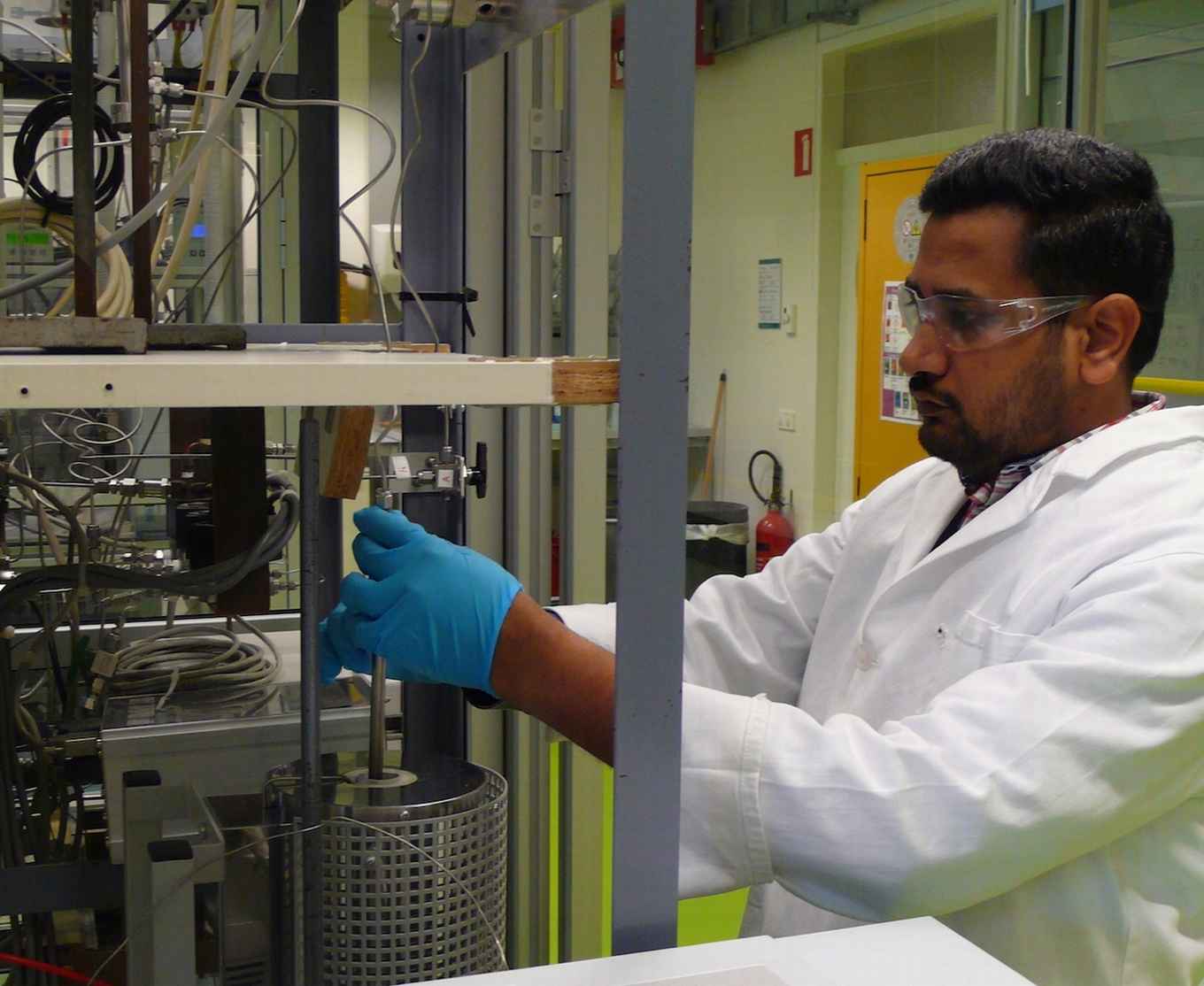

The researchers behind the catalyst, UvA chemists Edwin Gnanakumar and Shiju Raveendran, are in the process of commercialising the catalyst with the help of Amsterdam Innovation Exchange (IXA), the university’s technology transfer office.

From waste to resource

Carbon dioxide (or CO2) is a trace gas in earth’s atmosphere and plays a vital role in regulating the planet’s surface temperature by trapping heat. Although it forms an important part of the planet’s carbon cycle, CO2 is also known to be a potent greenhouse gas. Since the industrial revolution, the level of atmospheric CO2 has climbed steadily as a result of human activity and is believed to be behind the current episode of global warming.

In the field of chemistry, practical solutions are being sought to reduce atmospheric CO2 by using the gas as a resource rather than a waste product. However, using carbon dioxide as a raw material and converting it to useful chemicals or fuels is notoriously difficult because of the compound’s molecular stability. This stability poses severe challenges to attempts to activate or reactivate CO2.

Efficient conversion

Gnanakumar and Raveendran, who work within the UvA’s Sustainable Chemistry research priority area, have managed to address this activation problem by inventing a catalyst that can efficiently convert CO2 to CO at relatively mild conditions. The CO can then be converted to a number of common hydrocarbons with the use of existing technology, thus opening up an efficient way to utilise CO2. ‘It was an accidental discovery’, says lead researcher Raveendran. ‘We were experimenting for a different product, but the catalyst turned out to be highly selective for CO, better than any reported ones’.

The new catalyst is easily prepared and inexpensive. It can convert CO2 at ambient pressure and low temperatures. Longer-term tests in a flow reactor confirmed that the catalyst remains active, showing promise for the scale-up of applications such as industrial flue gas conversion. According to the researchers, the conversion can be easily adapted for handling large amounts of gases.

CAPITA

The work on the CO2 catalyst is part of the framework of the European research project CAPITA (Catalytic Processes for Innovative Technology Application), co-funded by the Netherlands Organisation for Scientific Research. The consortium also includes the University of Castilla-La-Mancha (Spain), the Technological Educational Institute of Sterea Ellada and the Chemical Process Engineering Research Institute (Greece) as well as three companies: Hellenic Petroleum Renewables (Greece), GRAPHENANO (Spain), and Delft Solid Solutions (Netherlands).