Four public-private research projects receive LIFT funding

6 February 2018

The LIFT funding (Launchpad for Innovative Technology) is intended for public-private co-operation of at least one company and at least one knowledge institute. Projects are funded for 1/4 by the industry and for 3/4 by the Netherlands Organisation for Scientific Research (NWO). Recently NWO announced the funding of eleven new projects for a total of three million euros. The following four LIFT projects involve HIMS scientists:

Where is all the polyester? – A new method for identification and quantification of polyester micro-fibre in river and seawater, and in sludge

Gert-Jan Gruter (UvA-HIMS) together with Heather Leslie (VU) and Ed de Jong (Avantium)

In this project, the researchers will detect polyester fibres in river and seawater, and in sludge. When washing polyester-containing clothing (such as fleece), hundreds of millions of small fibres are released. These are not or not completely retained in the filters of washing machines and water treatment facilities, and eventually end up in the oceans. Many millions of tons of polyester must have ended up in the sea in this way. Current sampling and analysis techniques can hardly reveal this PET. In this LIFT project the research groups of professors Gruter, Schoenmakers (also HIMS), and Leslie (VU) will tackle this challenge together with industrial partner Avantium. The researchers feel it is their responsibility to obtain a better understanding of the problems associated with current materials before new materials for packaging and fibres (textile) are to be commercialized. The findings of this project (and possibly follow-up research) should be used in the design of the materials of the future.

A robust and safe nickel (II) iron battery for storing fluctuating wind energy and solar energy

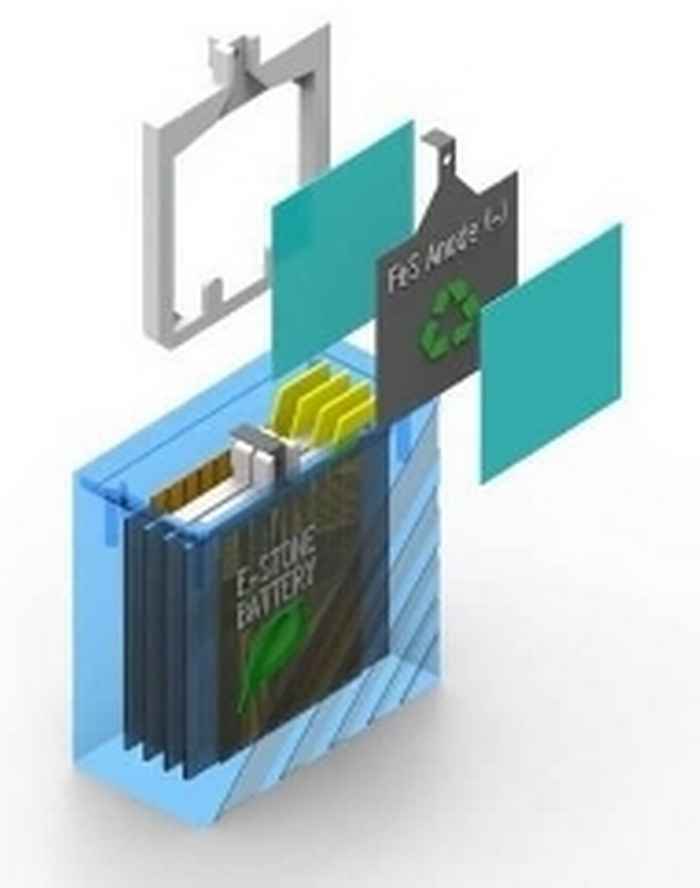

Fokko Mulder (TUD) together with Moniek Tromp (UvA-HIMS) and Thomas van Dijk (E-Stone BATTERIES)

Cheap energy storage is essential for a sustainable energy transition. In this project the innovative iron electrode of E-Stone is being further developed. In-depth research into the underlying working mechanism of this innovative electrode has not been carried out yet. A better understanding paves the way for the optimal production of a reliable battery; obtaining optimum control over the production process; selecting the right raw materials for the materials; and optimizing the energy efficiency in the long term, for many hundreds of cycles.

Development of heterogeneous catalysts for the selective alkylation of naphthalene and biphenyl

Shiju Raveendran (UvA-HIMS) together with Rudolf Koene (Rütgers Resins BV)

Naphthalene and biphenyl are important chemical intermediates. Their alkylated compounds are used for the manufacture of advanced polymers. In this project, the University of Amsterdam and Rütgers Resins BV will develop new solid catalysts for the efficient isopropylation of naphthalene/biphenyl in a continuous reactor.

Combining graphene with metal oxide nanoparticles: towards the development of new coating materials

Shiju Raveendran (UvA-HIMS) together with Hans van der Weijde (Tata Steel Netherlands)

Anti-corrosive coatings ensure long life-time for metal parts. Some of these coatings contain chromium compounds. However, these will have to be replaced in the near future by more environmentally friendly and non-toxic alternatives. In this project, the University of Amsterdam and Tata Steel B.V. will develop new anticorrosive coatings based on a combination of graphene and non-toxic metal oxides.