Utilizing lignocellulose from biomass for PEF production

Production and downstream integration of acidic hydrolysis into 5-(chloromethyl)furfural

18 December 2023

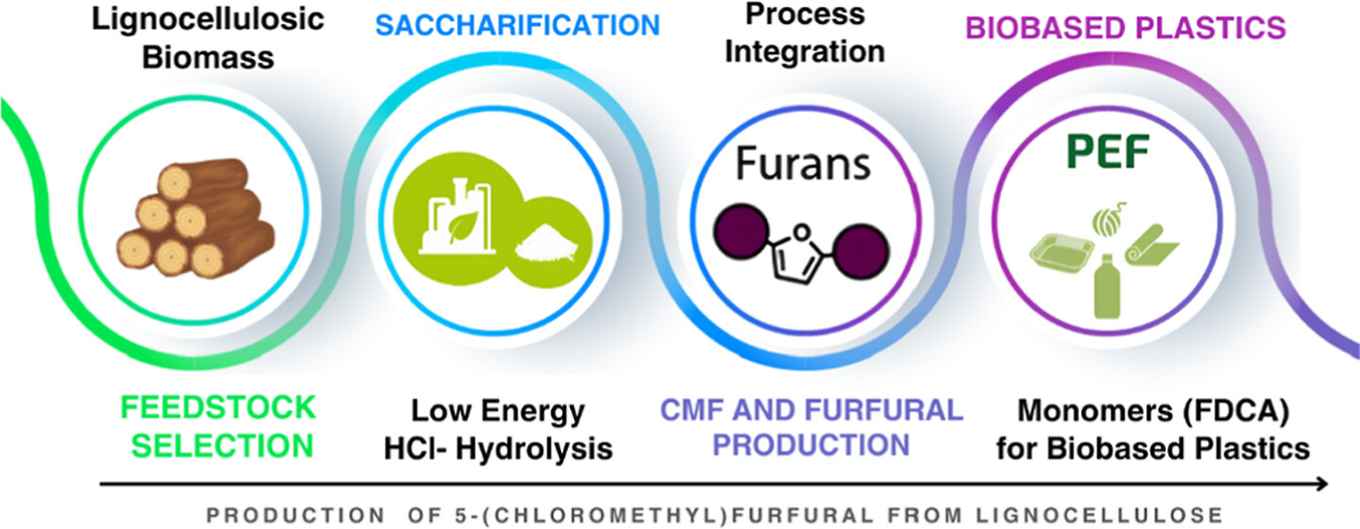

The transition of the chemical and plastics industry away from fossil feedstocks requires the development of alternative carbon sources. Lignocellulosic biomass is the most available ‘above-the-ground’ carbon source, but its industrial utilization is hampered by the lack of scalable technologies to viably provide alternatives to fossil-fuel-derived chemicals and/or materials at a world scale.

A first requirement for the valorization of lignocellulosic biomass is the complete saccharification of its sugar-bearing components. HCl-based technologies can achieve this at 20 °C and ambient pressure, as was already disclosed in the 1920s. However, the inability to economically separate sugars from acids has always impeded commercialization of this ‘Bergius’ process.

Integrated hydrolysis and conversion

In recent years, chemical technology company Avantium Chemicals has developed a modern version of this highly concentrated acid hydrolysis for its wood-based biorefinery. Here, the saccharides in HCl are transformed into furanics without any prior purification, in particular to 5-(chloromethyl)furfural (CMF). CMF is extracted in situ using immiscible organic solvents, allowing for an easy product separation. It serves as the building block for furan dicarboxylic acid (FDCA), the monomer for the production of polyethylene furanoate (PEF) polyester.

In his study at the Industrial Sustainable Chemistry group led by Avantium’s Chief Technology Officer Prof. Gert-Jan Gruter, Jorge Bueno Moron investigated the viability and optimization of the integrated process for acidic hydrolysis and saccharide conversion. He was able to predict the outcome of the CMF formation reaction from the hydrolyzed saccharides by applying design-of-experiment techniques, varying a broad range of reaction parameters. The research also focused on the downstream separation of the obtained furanics from the organic solvent by means of distillation.

Paper details

Jorge Bueno Moron, Gerard van Klink, and Gert-Jan M. Gruter: Production and Downstream Integration of 5-(Chloromethyl)furfural from Lignocellulose. ACS Sustainable Chemistry & Engineering Article ASAP. DOI: 10.1021/acssuschemeng.3c05525

See also

Research group Industrial Sustainable Chemistry