Plastic from CO2 and plants, for example for LEGO

New research group Industrial Sustainable Chemistry develops materials for a circular economy

17 January 2018

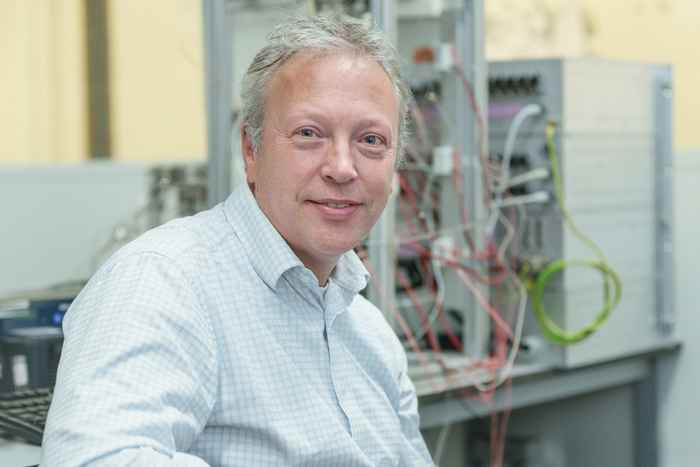

The development of a plastic from biomass or from CO2 for LEGO is a perfect example of the ambition of the new research group, located at the Van 't Hoff Institute for Molecular Sciences at the UvA. "Plastics from biomass are essentially CO2 neutral," says group leader Prof. Gert-Jan Gruter. "But they have more advantages: when using resources other than oil, such as sugars, completely new materials can be developed, with special properties." Yet it is their sustainability that urges their development: "To develop the new, sustainable materials that we need in 2050 we really have to get started today. It takes a lot of time to bring materials and processes to industrial growth."

The ISC group is closely linked to Avantium, the Dutch chemical company specialized in sustainable chemistry. Avantium successfully developed the sustainable PEF plastic from natural sugars, as an alternative to the PET bottle. In 2017 Avantium set up two research groups at the Amsterdam Science Park.. Gruter is Chief Technology Officer at Avantium and professor by special appointment at the university's Van 't Hoff Institute for Molecular Sciences for one day a week. His ISC group starts with two major and two smaller research projects, for which the first PhD students have now started their research. Gruter expects to employ ten PhD students within a few months.

'Green' LEGO bricks

The plastic for LEGO is part of the project Novel Rigid Bio-based Polyesters for potential large scale applications, in short RIBIPOL. It received funding from the Dutch Chemistry Innovation Fund of NWO, enabling the appointment of five PhD students. LEGO and Avantium also contribute to the project, both financially and in kind. The aim of the project is to create new biobased polyesters from commercially available building bricks and suitable for large-scale applications. Together with Avantium and toy manufacturer LEGO, the group hopes to develop 'green' materials for the production of fibres, packaging and the iconic building bricks.

The idea is to produce the polyesters through the polymerization of monomer building blocks from sugars (from plants) and oxalic acid (from CO2).

This is in line with technology developed by Avantium for the isolation of sugars from 'second-generation' biomass: natural materials that do not compete with food supply, such as wood chips, sawdust and agricultural residual products.

The second important ingredient, oxalic acid, is a fairly common chemical raw material. However, says Gruter, oxalic acid can also be produced from CO2. Avantium has patents to do precisely that, with the help of electricity. The company develops this technology in a large European research project called Ocean: Oxalic acid from CO2 using Electrochemistry At demonstratioN scale. It funds two PhD students at the UvA. Gruter: "Our idea is to produce oxalic acid from carbon dioxide with the help of sustainable electricity, so oxalic acid becomes a raw material for green chemistry. But since it is already available now, we can already start working on ways to use it for products. Such as plastics for injection molding, as with the LEGO bricks, but also new synthetic fibers, bottles and packaging foil. "

Synthesis and characterization of the new monomers and polymers will take place in the laboratories of both HIMS and Avantium. "The HIMS expertise in the field of catalysis and polymer analysis is of great importance," says Gruter. In this he cooperates with HIMS scientists Dr Raveendran Shiju and Prof. Peter Schoenmakers. An important aspect is to synthesize polymers with the right chain lengths (molecular weight) and properties. These properties can be further optimized by using so-called co-monomers, also of sustainable origin, naturally.

Investigating degradation

Gruter emphasizes that in his research potential applications are always in view. "We want the new materials to be used on a large scale, which means they can compete with existing fossil products regarding price and performance." He also looks at the degradability of the materials in the long term because the plastics - depending on the application - can end up in nature. For his he intends to cooperate with Dr John Parsons and Dr Albert Tietema of the Ecosystem & Landscape Dynamics group at the UvA's Institute for Biodiversity and Ecosystem Dynamics (IBED).

"Plastics in nature, especially microplastics in seawater, are increasingly becoming a problem," Gruter acknowledges. "If we develop new materials we need to learn from problems caused, unintentionally, by current materials." He started a collaboration with Dr Heather Leslie of VU University Amsterdam to develop a method for quantifying PET microfibers in seawater and sediment in the form of a PhD project. Gruter: "There is currently no simple method available for this. If we have no data on the quantities of microplastic in our oceans further research, for example on the effects on the food chain, is difficult to justify."

Communicating with consumers

What is special is that Gruter wants to gain insight into the way consumers will appreciate the new materials and their sustainability aspects. Gruter: "To accelerate the transition to CO2-neutral materials, it is very important that there is demand for them. We want to know how to communicate with consumers to get them interested in more sustainable plastics." This research will take place in collaboration with Dr Frenk van Harreveld, social psychologist at the UvA Faculty of Social and Behavioral Sciences, and with Prof. Bas Haring, Professor of Public Understanding of Science at Leiden University.