Negative thermal expansion design strategies in metal-organic frameworks

24 September 2019

In condensed matter, an increase in temperature generally leads to an increase in volume. In applications where materials are placed in confined environments, this phenomenon of positive thermal expansion (PTE) can cause significant stress or even catastrophic device failure. At material interfaces in coatings or films, a mismatch in thermal expansion properties can lead to cracking and peeling. The availability of materials with tailored thermal expansion behaviour would mitigate such problems and be of significant value for a variety of other material design and engineering challenges.

MOFs as an emergent class of materials with negative thermal expansion

Metal-organic frameworks (MOFs) are predicted to exhibit widespread negative thermal expansion (NTE), due in part to their nano-porosity and flexible framework characteristics. They are particularly intriguing as NTE materials since they offer great design flexibility - a characteristic which distinguishes them from NTE zeolite materials. MOFs are formed by the assembly of a great variety of inorganic nodes and multitopic organic ligands. The latter also enable a larger degree of structural flexibility which may further promote their potential for exhibiting large-scale NTE.

Design strategies for tailoring thermal expansion in microporous MOFs

The MOF design strategies now published in Advanced Functional Materials are the result of a collaborative American/Dutch effort where experimental research at Sandia Labs (Livermore, California, USA) and Georgia Tech (Atlanta, Georgia, USA) was supported by computer simulations performed by Dr Jurn Heinen and Dr David Dubbeldam of the Computational Chemistry group at the Van 't Hoff Institute for Molecular Sciences (Amsterdam, the Netherlands). Heinen also joined lead author Nicholas Burtch (Sandia) in collecting synchrotron-radiation diffraction data on many MOF samples at the Advanced Photon Source (APS) at Argonne National Laboratory (Lemont, Illinois, USA).

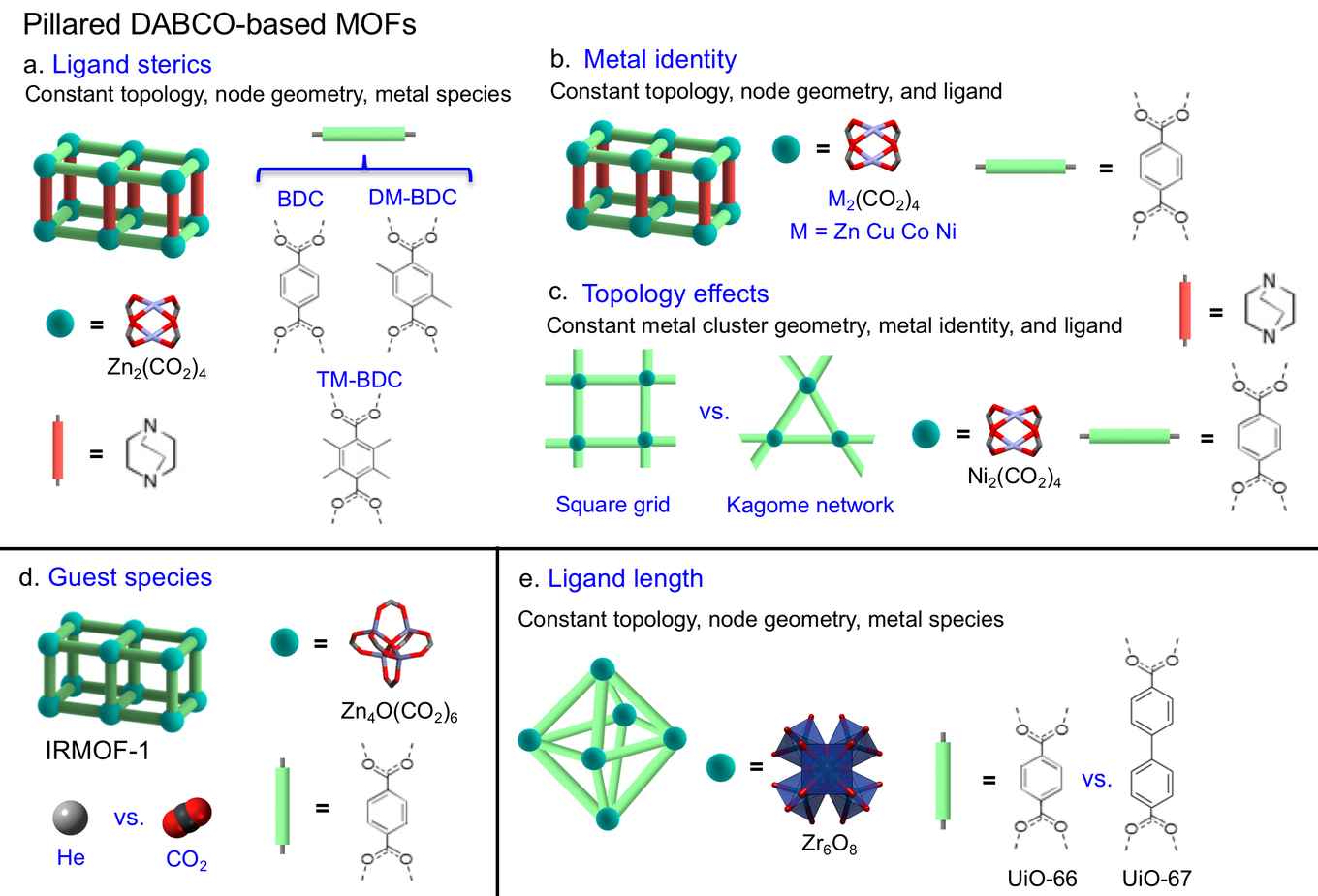

By independently varying the metal, ligand, topology, and guest species, the researchers established how MOF thermal expansion characteristics can be adjusted in the positive or negative direction. They present various design strategies for tailoring MOF thermal expansion behaviour by varying their structural properties and guest environment, as summarized in the figure below.

The researchers also publish a concise selection guide for isotropic NTE materials based on average values of the coefficient of thermal expansion reported for selected materials over various temperature ranges. Depending on the target application, MOFs can provide advantages over traditional material classes that include an extended range over which NTE is exhibited, improved chemical, mechanical, and thermal stability properties and, due to their porosity, the exploitation of guest environment as a thermal expansion control strategy. A large design space can be covered through further characterization of the thousands of MOFs that have already been synthesized and reported upon in literature. However, before becoming useful in composite material applications, studies have to be performed into how the nanoscale (crystallographic) negative thermal expansion found in MOFs translates to a reduction of the coefficient of thermal expansion at the macroscopic (bulk) scale.

More generally, a fundamental understanding of MOF thermal expansion is crucial to advancing their use in a wide range of potential applications that include coated monoliths, microcantilever sensors, and electronic devices. In each of these scenarios, changes in temperature will arise, and a mismatch in the average coefficient of thermal expansion of the MOF and its substrate material will produce residual stresses that can lead to cracking and peeling behaviour or compromise the adhesion between the MOF and its interfaced layer.

Publication details

Nicholas C. Burtch, Samuel J. Baxter, Jurn Heinen, Ashley Bird, Andreas Schneemann, David Dubbeldam, Angus P. Wilkinson: Negative Thermal Expansion Design Strategies in a Diverse Series of Metal-Organic Frameworks. Advanced Functional Materials, first published: 18 September 2019. DOI: 10.1002/adfm.201904669.