PFAS-free synthesis of fluorinated pharmaceutical and agrochemical compounds

29 August 2024

The straightforward and effective method was developed at the Flow Chemistry group at the Van ‘t Hoff Institute for Molecular Sciences led by Prof. Timothy Noël, in cooperation with researchers in Italy, Spain and the UK, both from academia and industry. Applying the principles of flow chemistry, where reactions take place in closed systems of small tubes, makes for safe and controlled chemistry. It also offers greater versatility and flexibility over more common procedures using traditional chemical glassware.

Environmentally more friendly

Many pharmaceutical compounds (such as anti-depressants) as well as agrochemical compounds (such as pesticides) benefit from the presence of a trifluoromethyl (-CF3) group. It enhances hydrophobicity and increases metabolic stability, thus improving efficacy and lowering the required dose or concentration.

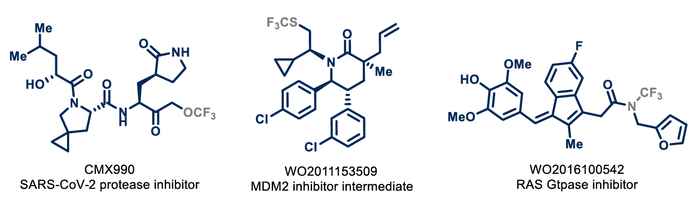

To introduce the fluorine atoms in these molecules, their synthesis often requires bespoke fluorinated reagents. Many of these are among the family of PFAS compounds and thus will face future legislation. The synthesis protocol now presented in the Science paper provides a viable alternative since it only requires caesium fluoride salt as the fluorine source. Such PFAS-free synthesis of fluorinated agents can provide an environmentally more friendly option for the synthesis of pharmaceutical compounds, which motivated scientists from AstraZeneca to participate in the research.

In addition, the new synthesis protocol enables coupling of the CF3 group through a sulphur (S), nitrogen (N) or oxygen (O) atom. Such fluorinated motifs confer unique features to drug molecules and agrochemicals, impacting their lipophilicity, oxidation resistance, and acid-base properties.

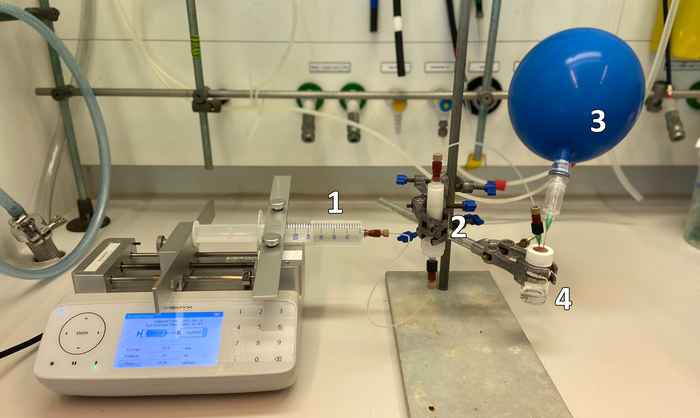

Integrated flow system

The Science paper presents a versatile microfluidic flow module for generating reactive N–, S– and O–CF3 anions. These are prepared in a packed bed flow reactor containing the caesium fluoride salt. Appropriate (S, O or N containing) precursors are then led through this reactor.

There, they are fluorinated with high efficiency due to the high surface area of the salt in the packed bed as well and the improved mixing of the organic intermediates. Importantly, this approach also offers enhanced safety as all formed intermediates are contained within the microfluidic system.

Another important feature of the flow system described in Science is the integration of the anion generating module with a downstream reaction module. There, the N–, S– or O–CF3 anions react with appropriate substrates to achieve pharmaceutical and agrochemical active ingredients as the desired end products.

Implementation in an academic and industrial context

In combination, the anion generator module and the downstream reactor provide a streamlined platform for the derivatization of molecules bearing N–, S– and O–CF3 motifs. This innovative approach is poised to impact the development of new pharmaceutical drugs by enhancing their properties while improving safety and sustainability in their production processes. In their Science paper, the researchers report the combination of various anions with a range of substrates, resulting in multiple fluorinated products with relevance to pharmaceutical and agrochemical syntheses. In many cases the research team was able to report very satisfactory yields. Moreover, the operational parameters (e.g. reaction times) offer a good prospect for actual implementation in an academic as well as an industrial context.

Paper details

Mauro Spennacchio, Miguel Bernús, Jelena Stanić, Daniele Mazzarella, Marco Colella, James J. Douglas, Omar Boutureira, Timothy Noël: A unified flow strategy for the preparation and use of trifluoromethyl-heteroatom anions. Science, 385, 6712, p991-996 DOI: 10.1126/science.adq2954