An automated photoreactor for sustainable conversion of carbon dioxide

Offering a highly reproducible method for assessing and optimizing catalysts

22 November 2024

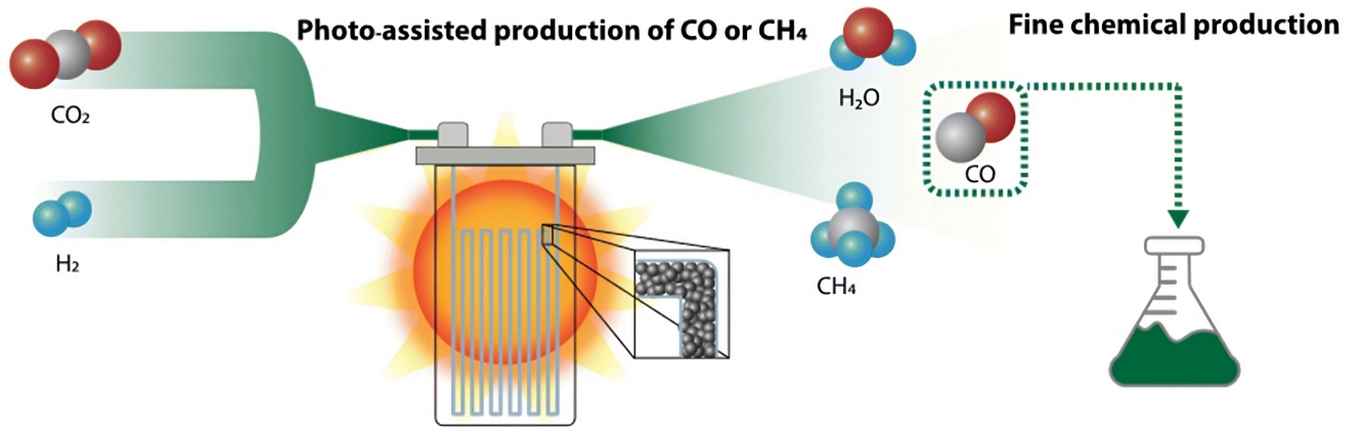

The reactor offers a highly reproducible method for assessing and optimizing catalysts by integrating automation, a precise control of parameters (flow rate, temperature, light intensity, and pressure), and modularity. At the heart of the system is a packed-bed where catalysts are deposited on glass beads. Its construction relies on commercially available components and open-source software, establishing a flexible and accessible framework for automation.

A key feature of the system is its integration with downstream processes, allowing immediate utilization of carbon dioxide-derived products. Methane, produced as a validation step, can serve as a precursor for fine chemical synthesis, while the system’s ability to generate carbon monoxide on demand opens new possibilities for carbonylative cross-coupling reactions.

Abstract, as published with the paper

Continuous-flow methodologies offer promising avenues for sustainable processing due to their precise process control, scalability, and efficient heat and mass transfer. The small dimensions of continuous-flow reactors render them highly suitable for light-assisted reactions, as can be encountered in carbon dioxide hydrogenations. In this study, we present a reactor system emphasizing reproducibility, modularity, and automation, facilitating streamlined screening of conditions and catalysts for these processes. The proposed commercially available photoreactor, in which carbon dioxide hydrogenation was conducted, features narrow channels with a high-surface area catalyst deposition. Meticulous control over temperature, light intensity, pressure, residence time, and reagent stoichiometry yielded the selective formation of carbon monoxide and methane using heterogeneous catalysts, including a novel variant of ruthenium nanoparticles on titania catalyst. All details on the automation are made available, enabling its use by researchers worldwide. Furthermore, we demonstrated the direct utilization of on-demand generated carbon monoxide in the production of fine chemicals via various carbonylative cross-coupling reactions.

Paper details

Jasper H. A. Schuurmans, Tom M. Masson, Stefan D. A. Zondag, Simone Pilon, Nicola Bragato, Miguel Claros, Tim den Hartog, Francesc Sastre, Jonathan van den Ham, Pascal Buskens, Giulia Fiorani and Timothy Noël: Light-assisted carbon dioxide reduction in an automated photoreactor system coupled to carbonylation chemistry. Chem Sci. 2024, Nov 8. DOI: 10.1039/D4SC06660J