Hydrothermal liquefaction shows promise for advanced recycling of post-consumer plastics

Towards plastics circularity through chemical recycling of polyolefins in urban-industrial symbiosis

10 July 2025

The research was carried out in collaboration with the Spanish waste recycling company COGERSA and Total Energies. These are both partners in PLASTICE, a €20 million EU-funded project led by the Spanish technology research centre CIRCE. The project aims to develop four distinct pathways for the valorisation of different types of post-consumer plastic and textile waste. Raveendran leads the development of hydrothermal liquefaction (HTL) as a promising technology for converting plastic waste.

High oil yields

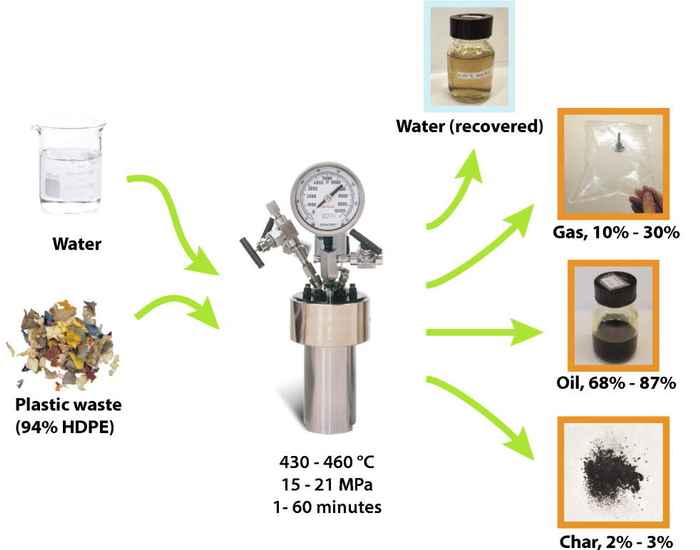

In the study now published in Chemical Engineering Journal, liquefaction was applied to convert post-consumer plastics waste that originated from actual Spanish municipal waste. Consisting predominantly of high-density polyethylene (93% in weight), it was processed into oil, gas, and char. The process achieved high oil yields (up to 87 % in weight), with limited gas production and minimal char formation. A detailed study of the process parameters revealed that higher temperatures and longer conversion times reduce yield but produce lighter, aromatic-rich oils. Increased water-to-plastics ratios lower yield and produce heavier oils, while the higher water content boosts alkene selectivity and lowers aromatic content.

The produced HTL-oil can be further processed to yield monomers that can be used to produce virgin plastic materials. This closes the loop in the chemical recycling of polyolefins, fostering an innovative approach for urban-industrial symbiosis and a circular economy. The aim now is to bring the process towards pilot scale in cooperation with COGERSA. The produced high-quality synthetic oil will be further upgraded by Total Energies into a suitable feedstock for the production of olefins.

Abstract, as published with the paper

Plastic waste presents significant environmental challenges, driving research into chemical recycling. High-density polyethylene (HDPE) is particularly difficult to recycle among common plastics due to its stability. Hydrothermal liquefaction (HTL) technology has emerged as a promising method to address these issues. The oil properties were found to be adjustable based on reaction parameters: lower temperatures (430 °C) and shorter reaction times (1 min) produced heavier oils with a high saturated alkanes content, whereas higher temperatures (460 °C) and extended reaction times (60 min) yielded lighter oils with an increased aromatics content. Additionally, a higher water-to-plastic ratio favored alkenes production, resulting in a heavier oil with a limited aromatics fraction. This research illustrates the strong potential of HTL to transform real post-consumer plastic waste streams into new plastic monomers, thereby closing the loop in the chemical recycling of polyolefins and fostering an innovative approach for urban-industrial symbiosis and a circular economy.

Paper details

Shih-Chieh Chien, Hongqi Wang, Ahmad A.L. FARRA, Laura Megido, José Manuel González-LaFuente, N. Raveendran Shiju: Toward circular plastics: chemical recycling of high-density polyethylene-rich municipal waste using hydrothermal liquefaction. Chemical Engineering Journal, 2025, 165513. DOI: 10.1016/j.cej.2025.165513

See also

- PLASTICE: Closing the plastics loop with novel conversion routes

- Research group Shiju Raveendran: Catalysis Engineering